With the Lean & six sigma efforts and operations excellence focus, businesses operate much more efficiently today. Lean methodologies have matured and have been embraced by a majority of organizations. In the Industrial segment, Lean methods are continuously applied to shop operations to remove waste & improve efficiency of labor, material, time, and space and generate tangible savings. These gains are in the range of 3%-5% – sufficient to offset annual inflation and foreign exchange fluctuations impact on gross margin of the business. But a third and a larger head wind from competitive pricing forces pricing discounts and erodes gross margin of the products. Cash cows turn into loss leaders and ultimately profitability of the business is reduced. Price pressures can be offset and product gross margin maintained and even improved by reducing direct material cost of the product (material used in the product).

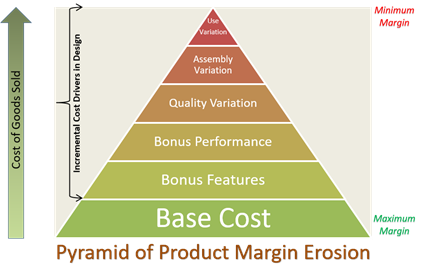

In Industrial products, cost of goods sold, COGS is 65%-70% of total revenue, and in COGS direct material cost is ~ 70%. Consequently, direct material cost is ~ 45%-50% of total revenue. Direct material cost is a result of product features, performance specifications and design. It is a significant portion of the top line but not in the scope of operations excellence cost reduction methods. Product cost related to features, performance and design are assumed to be sacrosanct or follow a ‘if ain’t broke don’t fix it’ mind set.

Lack of applying a robust process to analyze product cost drivers, must have vs. good to have features, fear of customer push back prevents a review of direct material cost. An opportunity of 15%-20% cost reduction of direct material spend is left on the table

During the development of the product, speed to market and budgetary constraints do not permit marketing and product managers to conduct ‘voice of the customer’ research. To avoid disappointing the customer and hurt sales, product features and performance requirements are over specified by the product team. In addition to extra features and performance requirements, the design team has to ensure out of the box product quality as well as consistent performance over the life of the product. This team also makes assumptions on variations product will experience in the customer environment, supplier quality and production process. They add safety margin (material & cost) to the design to reduce risk of failure due to unknown variations. There are other factors which contribute to higher product cost but the main have been described above.

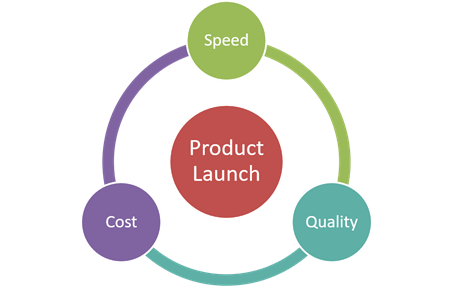

The genesis of high product cost is in the new product development cycle. An optimum new product launch consists of three deliverables of the product:

-

Speed to market – maximize revenue

-

Quality – delight the customer

-

Cost – maximize profitability

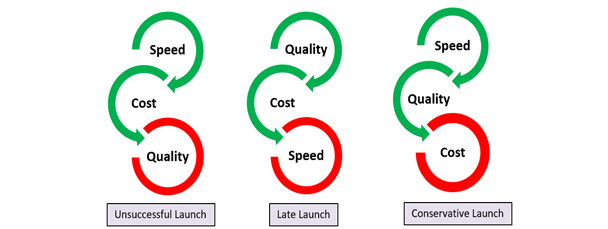

Majority of the businesses are not able to hit all three targets of speed, quality & cost at product launch and wisely choose speed & quality over optimum cost for a successful commercialization.

This conservative approach adopted by the businesses inflates COGS by 10%-15%